How Swivel Casters Revolutionize Equipment Mobility

Introduction

Modern businesses demand efficiency, flexibility, and safety in the workplace, especially where heavy and sensitive equipment is involved. Swivel casters have become essential, transforming how equipment is moved and manipulated across numerous industries. By enabling 360-degree rotation, swivel casters support superior maneuverability, facilitating smoother operations in environments requiring constant equipment repositioning. For tasks requiring robustness, using heavy duty casters ensures that even the most substantial loads can be moved easily and securely.

Incorporating swivel casters into carts, machines, and tools allows operators to glide through narrow aisles and congested spaces with minimal effort. This improved movement is not just about convenience—it’s about enhancing productivity and protecting workers from unnecessary strain. The right casters elevate operational efficiency and safety, becoming an indispensable part of equipment design.

Swivel casters stand out compared to traditional fixed casters. Fixed casters restrict equipment to straight-line movement, often causing frustration in dynamic environments. Swivel casters, on the other hand, adapt to quick directional changes. This adaptability prevents workplace logjams and costly downtime, especially on fast-paced manufacturing floors or bustling hospital corridors.

With technological advancements, the possibilities for caster customization have expanded. Standard casters now incorporate features once reserved for specialized applications, such as non-marking wheels, silent operation, and environment-specific coatings. Businesses now expect more from casters than just basic mobility—they want ergonomic designs, durable materials, and specialized features tailored to unique operational needs.

Table of Contents

Understanding Swivel Casters

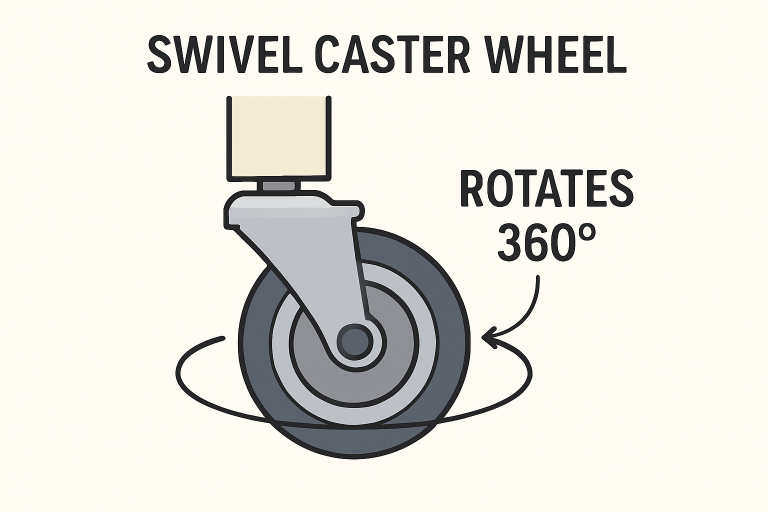

The construction of a swivel caster ensures premium maneuverability. Each swivel caster has a wheel fastened within a fork attached to a rotating bearing. This assembly grants a full 360-degree spin, so the equipment can change direction instantly and glide around barriers or corners. This design underpins their immense popularity in settings ranging from industrial warehouses to retail shops.

The key to effective movement is the smoothness of the swivel and the quality of materials used. Steel ball bearings, sturdy fork housing, and wheels made from polyurethane or rubber all contribute to seamless navigation. Premium designs improve functionality and extend caster life, reducing replacement costs and fostering operational dependability. According to IndustryWeek, innovative material choices make swivel casters even more reliable in demanding conditions.

Enhancing Workplace Ergonomics

One of the most significant advantages of swivel casters is their impact on workplace ergonomics. Moving heavy loads places severe strain on the body. Poor mobility solutions increase the risk of back injuries, sore joints, and repetitive strain issues among staff handling carts or equipment daily. Swivel casters limit these risks with smoother, easier motion, especially when engineered with ergonomic bearings and soft-tread wheels.

Some ergonomic caster designs include integrated shock absorption, reducing jarring movements when transporting delicate goods or medical equipment. This safeguards the cargo and ensures user comfort and safety. By adopting ergonomic-focused casters, enterprises can meet safety regulations and demonstrate a real commitment to worker well-being, which is increasingly essential in today’s workplace culture.

Applications Across Industries

Swivel casters have diverse applications, proving their worth far beyond simple warehouse utility:

- Healthcare: Hospital beds, IV stands, surgical carts, and diagnostic equipment must be easily maneuvered for patient care. Swivel casters with locking mechanisms allow for precise placement and strict safety protocols within fast-moving medical settings.

- Manufacturing: Modern production lines depend on the agile movement of components and materials. Swivel casters lower manual labor needs and streamline production flow, improving throughput and minimizing bottlenecks.

- Retail: Thanks to reliable casters, display units, shopping carts, and mobile shelving enhance store layout flexibility. Staff can quickly reorganize spaces in response to changing inventory or seasonal promotions.

Industries from aviation to hospitality now regard swivel casters as essential to smooth day-to-day functions.

Innovations in Caster Technology

Advances in caster engineering have brought innovative features tailored to specialized needs. More manufacturers now offer shock-absorbing casters that guard sensitive items from damage on uneven floors, which is vital for laboratories and electronics assembly. Antimicrobial coatings play a crucial role in healthcare and food service environments by reducing cross-contamination risks and ensuring compliance with hygiene standards.

- Shock-Absorbing Casters: Protect sensitive equipment by minimizing vibrations on bumpy surfaces.

- Antimicrobial Coatings: Help inhibit the growth of bacteria and maintain cleanliness standards essential in hospitals and commercial kitchens.

- Advanced Braking Systems: These systems keep carts and equipment securely in place during loading, unloading, or important tasks, increasing on-site safety.

As businesses continue to demand higher performance, innovative designs like maintenance-free casters and automatic locking mechanisms are setting new standards throughout the industry.

Choosing the Right Swivel Caster

Not all casters are created equal. The right caster selection factors in load weight, wheel composition, and wheel size. Each aspect plays a role in performance and longevity:

- Load Capacity: Casters must be rated to safely carry the equipment’s weight. Overloading can result in component failure or workplace accidents.

- Wheel Material: Different settings require specific wheel types—rubber wheels work best on rough floors, while polyurethane wheels protect delicate tiles and offer quieter motion.

- Wheel Size: Larger wheels overcome gaps or debris and demand less effort to move, a significant advantage in busy environments with changing floor conditions.

Tailoring your caster choice to your specific environment guarantees the reliability and workplace safety of your equipment for years to come.

Conclusion

Swivel casters are a quiet revolution in mobility, driving efficiency, ergonomic safety, and adaptability across sectors. Employing high-quality swivel casters allows organizations to future-proof their operations, mitigate injury risks, and maximize productivity. Appreciating their role—whether for supporting sensitive equipment, maximizing tight workspace use, or simply making loads lighter—positions businesses for success in today’s demanding operational climates.